Size rivnut for 8mm factory holes?

- Thread starter robthehungrymonkey

- Start date

sparkplug

Well-known member

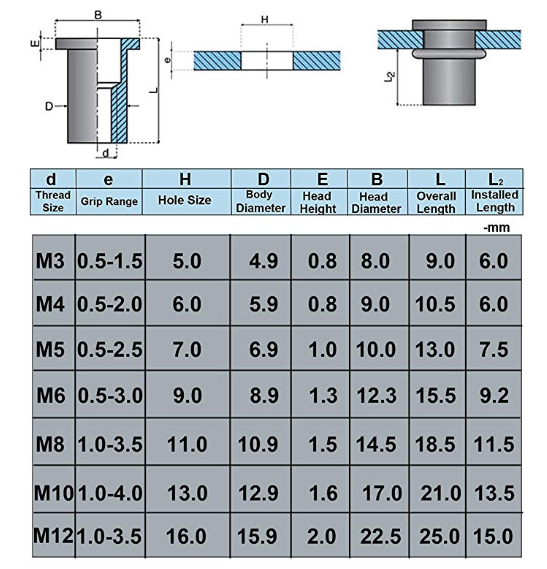

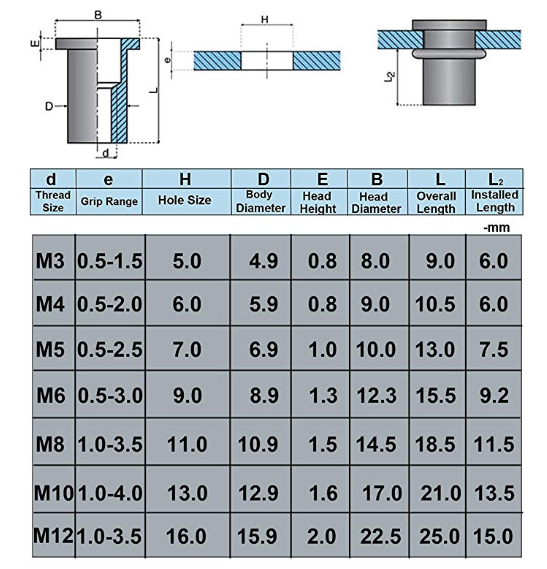

For an 8mm hole you will probably want an M5.5 according to this table

It's just one of those in-between sizes which doesn't quite work.

Easy enough to drill out to 9mm and put an M6 into it I would have thought.

Not sure where you got your figures from as they don't seem to agree with the chart. A couple of other online charts seem to be giving the same results which is why I'm questioning your figures - I'm no expert, I just remember having had a similar issue a couple of years ago and googled the figures again, so I'm quite happy to be proved wrong!

It's just one of those in-between sizes which doesn't quite work.

Easy enough to drill out to 9mm and put an M6 into it I would have thought.

Not sure where you got your figures from as they don't seem to agree with the chart. A couple of other online charts seem to be giving the same results which is why I'm questioning your figures - I'm no expert, I just remember having had a similar issue a couple of years ago and googled the figures again, so I'm quite happy to be proved wrong!

robthehungrymonkey

Member

Thanks, M5.5 is probably right (I've tried M5 and M6). I measured it myself with a caliper, so it's a bit strange the table is different.

I'd rather avoid drilling, the extra effort and clean up is a bit annoying! I'm going to try and find a hardware store today with different sizes in stock (harder than it sounds) and see what I can find.

I'd rather avoid drilling, the extra effort and clean up is a bit annoying! I'm going to try and find a hardware store today with different sizes in stock (harder than it sounds) and see what I can find.

sparkplug

Well-known member

apologies, I was attempting to be humorous with my M5.5 comment

To the best of my knowledge no such thing exists.

I guess you could possibly go the other route and go for a smaller size rivnut and put washers with the correct diameter hole in front and behind the existing van holes (assuming you can access both sides)

If you do decide to drill, then a good tip is to place a magnet near the hole to catch the swarf as you're drilling. Saves a lot of time in clean up. And don't forget to paint the edges afterwards so they don't rust.

To the best of my knowledge no such thing exists.

I guess you could possibly go the other route and go for a smaller size rivnut and put washers with the correct diameter hole in front and behind the existing van holes (assuming you can access both sides)

If you do decide to drill, then a good tip is to place a magnet near the hole to catch the swarf as you're drilling. Saves a lot of time in clean up. And don't forget to paint the edges afterwards so they don't rust.

@robthehungrymonkey I'm going to be using rivnuts too. Drilling out to 9mm, paint and then an M6 rivnut - stainless steel so they don't corrode. Using them for all ceiling battens, wall panels and overhead cabinets so they're removable.

#10-32 pre-bulbed plus nut hole size is 8mm.

plusnut size chart

plusnut size chart

robthehungrymonkey

Member

I've ordered some riv nuts of that size, thanks.#10-32 pre-bulbed plus nut hole size is 8mm.

plusnut size chart

Do you have a suggestion for where to buy plus nuts for a reasonable price? I was planning on using plus nuts for the more substantial loads but they seem very expensive.

There are a couple places that sell for reasonable prices in small quantities. I ordered from Liberty. 1/4-20 plusnuts were $0.25 each. I don't know what the minimum is but I ordered 140 and was $58 with tax and shipping.

Liberty Engineering Rivnut® or Rivet Nut Fasteners and Self Locking Nuts

Rivnut® or Rivet Nut Fasteners and Self Locking Nuts

www.libertyeng.com

Eric Experience

Well-known member

Rob.

There are lots of rivnut sizes, I use a lot on my builds. One variation uses external splines which works well with slightly over size holes. It is a shame that the big supermarkets control the fastener market in the states. Fasteners made in Europe are higher quality and cheaper than supermarket junk. Eric.

There are lots of rivnut sizes, I use a lot on my builds. One variation uses external splines which works well with slightly over size holes. It is a shame that the big supermarkets control the fastener market in the states. Fasteners made in Europe are higher quality and cheaper than supermarket junk. Eric.

Just found this thread and I'm wondering how those 10-32 Rivet nuts worked for your Sprinter. I see they're available from McMaster-Carr. Did you order the 0.020-0.130 material thickness? How have they weathered the test of time? TIA for your thoughts.I've ordered some riv nuts of that size, thanks.

Do you have a suggestion for where to buy plus nuts for a reasonable price? I was planning on using plus nuts for the more substantial loads but they seem very expensive.

autostaretx

Erratic Member

Mine is a 2023 Crew Van. I'm confused. If I go with metric sizes, and I should since the whole van is metric, the inside diameter of the hole is 8.0 mm, so what size in metric drill bit and plus nut/and/or/rivet nut should I use? TIAFor fitting into many of the T1N Sprinter's holes, i found Plus Nuts as being far more forgiving of "loose" fits.

View attachment 264045

--dick

ECU

2006 T1n 118 Sprinter

One of the issues is finding the right size that fits the hole. Then the bolt that fits that thread are going to be smaller.

I went with 1/4 x20 threads since this is used in furniture and there are lots of choices for screws, bolts and such.

That is an M6 in metric.

It required drilling.

Your request is :

M5X0.8 ISO 3.30 - 5.70 7.60-7.75 7.520 0.480 8.640 14.86 8.00 BRKS-580-5.7

The thread is a M5. This might not work as it is 3 to 5.7 mm depth.

I went with 1/4 x20 threads since this is used in furniture and there are lots of choices for screws, bolts and such.

That is an M6 in metric.

It required drilling.

Your request is :

M5X0.8 ISO 3.30 - 5.70 7.60-7.75 7.520 0.480 8.640 14.86 8.00 BRKS-580-5.7

The thread is a M5. This might not work as it is 3 to 5.7 mm depth.

autostaretx

Erratic Member

(@ECU and i were tippy-tapping at the same time)

Here in the US (you are doing a Dodge), Imperial fittings are far easier to find thanwasting spending time seeking metric.

(certainly if i'm using a threaded stud or fixed nut supplied by MB, i go metric)

As you're finding out, that falls into a definite gap in the PlusNut catalog (metric or Imperial)

The 10-32 PlusNut has a body diameter of 0.272 inches, and fits a hole spanning 0.273 to 0.278 inches. (shy of 8mm by 0.037 inch)

The next size up is 1/4-20 (which i used): body diameter 0.346 inches, hole from 0.347 to 0.352 inches.

The metric PlusNuts have a similar gap:

M5x0.8 has a body diameter of 7.48mm, for a hole size of 7.62 to 7.47 mm (shy by 0.53 mm : 0.021 inch)

and the

M6x1.0 has a diameter of 8.80mm suitable for a hole size of 8.93 to 8.79 mm

So for the closest (loose) fit, the M5 x 0.8 PlusNut comes the closest. 0.53 mm undersized instead of the 10-32 0.9 mm undersized.

Despite the PlusNut's *specifications* being too small for an 8mm hole, the width of the "squashed" retention metal would still work in that hole.

Unlike the RivNuts, they do NOT require a "precision" hole for their grip. They do not have "teeth" to engage the edge of the metal.

(the one on the left is a real PlusNut, the one on the right is a knock-off)

PlusNuts handle loose tolerances very well.

--dick

I am exceedingly agnostic about "metric" versus "Imperial" when it comes to what i use for "converting" my Sprinter.Mine is a 2023 Crew Van. I'm confused. If I go with metric sizes, and I should since the whole van is metric

Here in the US (you are doing a Dodge), Imperial fittings are far easier to find than

(certainly if i'm using a threaded stud or fixed nut supplied by MB, i go metric)

Let's see ... 8mm is 0.31496 inches ( just over 5/16ths of an inch (5.0394) ((and well below 41/128ths)), the inside diameter of the hole is 8.0 mm, so what size in metric drill bit and plus nut/and/or/rivet nut should I use? TIA

As you're finding out, that falls into a definite gap in the PlusNut catalog (metric or Imperial)

The 10-32 PlusNut has a body diameter of 0.272 inches, and fits a hole spanning 0.273 to 0.278 inches. (shy of 8mm by 0.037 inch)

The next size up is 1/4-20 (which i used): body diameter 0.346 inches, hole from 0.347 to 0.352 inches.

The metric PlusNuts have a similar gap:

M5x0.8 has a body diameter of 7.48mm, for a hole size of 7.62 to 7.47 mm (shy by 0.53 mm : 0.021 inch)

and the

M6x1.0 has a diameter of 8.80mm suitable for a hole size of 8.93 to 8.79 mm

So for the closest (loose) fit, the M5 x 0.8 PlusNut comes the closest. 0.53 mm undersized instead of the 10-32 0.9 mm undersized.

Despite the PlusNut's *specifications* being too small for an 8mm hole, the width of the "squashed" retention metal would still work in that hole.

Unlike the RivNuts, they do NOT require a "precision" hole for their grip. They do not have "teeth" to engage the edge of the metal.

(the one on the left is a real PlusNut, the one on the right is a knock-off)

PlusNuts handle loose tolerances very well.

--dick

ECU

2006 T1n 118 Sprinter

One other tip. Bolt tightness.

tighten your attachment bolts too tight and the nuts spin. You'll never get them off.

My solution is to use my drill gun set at the lowest power, like 2 out of 16.

This is enough to hold things to the wall and they don't rattle loose. And they are removable.

I've also placed a couple drops of superglue along the edge of the nut after install. I don't know if this helps or not. After drilling out ones I got too tight, I tried several things to avoid it in the future.

tighten your attachment bolts too tight and the nuts spin. You'll never get them off.

My solution is to use my drill gun set at the lowest power, like 2 out of 16.

This is enough to hold things to the wall and they don't rattle loose. And they are removable.

I've also placed a couple drops of superglue along the edge of the nut after install. I don't know if this helps or not. After drilling out ones I got too tight, I tried several things to avoid it in the future.

autostaretx

Erratic Member

You asked about drill bits... i'm not casually familiar with metric drill sizes.

For a *tight* fit around the M5 x 0.8 PlusNut, you would want a 7.48 mm (0.2945 inch) drill.

You could probably round that up to 7.5 mm

In the US "Letter Drill" size system, that would be an "M" drill: 0.295 inch, 7.49 mm Perfect!

In the fractional drills, a 19/64ths drill would be 0.2969 inch, 7.54 mm. Only 2 thousandths of an inch bigger than the "M".

But that's only if you're trying to put a PlusNut into sheet metal that doesn't have an existing 8mm hole (your choice).

The bolt hole to meet it would be 5 mm

--dick

p.s. with PlusNuts, the tighter they're set, the less likely they are to spin. My dealer installed the rear door grab bars with RivNuts... one spun.

So one of the grab bar bolts cannot be fully tightened or loosened for removal/replacement. Grump.

For a *tight* fit around the M5 x 0.8 PlusNut, you would want a 7.48 mm (0.2945 inch) drill.

You could probably round that up to 7.5 mm

In the US "Letter Drill" size system, that would be an "M" drill: 0.295 inch, 7.49 mm Perfect!

In the fractional drills, a 19/64ths drill would be 0.2969 inch, 7.54 mm. Only 2 thousandths of an inch bigger than the "M".

But that's only if you're trying to put a PlusNut into sheet metal that doesn't have an existing 8mm hole (your choice).

The bolt hole to meet it would be 5 mm

--dick

p.s. with PlusNuts, the tighter they're set, the less likely they are to spin. My dealer installed the rear door grab bars with RivNuts... one spun.

So one of the grab bar bolts cannot be fully tightened or loosened for removal/replacement. Grump.

Last edited:

I live near a United Fastener shop and they have metric bolts, too. I brought my van to them because they've helped me before and they have a super nice caliper to help me out and measure for me. Bear with me, as I'm trying to grasp the #s here. In general, you're saying the Plusnuts are a better fit because they are far better at being forgiving for "loose fits" and do NOT require a precision hole. The M5 X 0.8 plusnut is shy by 8.0 mm by 0.53while the 10/32 is shy of the 8 mmm by 0.037. Wouldn't the 10/32 be the better fit?(@ECU and i were tippy-tapping at the same time)

I am exceedingly agnostic about "metric" versus "Imperial" when it comes to what i use for "converting" my Sprinter.

Here in the US (you are doing a Dodge), Imperial fittings are far easier to find thanwastingspending time seeking metric.

(certainly if i'm using a threaded stud or fixed nut supplied by MB, i go metric)

Let's see ... 8mm is 0.31496 inches ( just over 5/16ths of an inch (5.0394) ((and well below 41/128ths))

As you're finding out, that falls into a definite gap in the PlusNut catalog (metric or Imperial)

The 10-32 PlusNut has a body diameter of 0.272 inches, and fits a hole spanning 0.273 to 0.278 inches. (shy of 8mm by 0.037 inch)

The next size up is 1/4-20 (which i used): body diameter 0.346 inches, hole from 0.347 to 0.352 inches.

The metric PlusNuts have a similar gap:

M5x0.8 has a body diameter of 7.48mm, for a hole size of 7.62 to 7.47 mm (shy by 0.53 mm : 0.021 inch)

and the

M6x1.0 has a diameter of 8.80mm suitable for a hole size of 8.93 to 8.79 mm

So for the closest (loose) fit, the M5 x 0.8 PlusNut comes the closest. 0.53 mm undersized instead of the 10-32 0.9 mm undersized.

Despite the PlusNut's *specifications* being too small for an 8mm hole, the width of the "squashed" retention metal would still work in that hole.

Unlike the RivNuts, they do NOT require a "precision" hole for their grip. They do not have "teeth" to engage the edge of the metal.

View attachment 264082

View attachment 264083

(the one on the left is a real PlusNut, the one on the right is a knock-off)

PlusNuts handle loose tolerances very well.

--dick

"So for the closest (loose) fit, the M5 x 0.8 PlusNut comes the closest. 0.53 mm undersized instead of the 10-32 0.9 mm undersized." Is the 0.9 a typo or the 0.037 further up in your explanation. I appreciate the explanation. I'm trying to understand all the nuances of reading the chart sizes posted.

Are you saying the depth isn't enough to support a lot of weight? Seems to me there's a good bit of space behind those 8mm holes.One of the issues is finding the right size that fits the hole. Then the bolt that fits that thread are going to be smaller.

I went with 1/4 x20 threads since this is used in furniture and there are lots of choices for screws, bolts and such.

That is an M6 in metric.

It required drilling.

Your request is :

M5X0.8 ISO 3.30 - 5.70 7.60-7.75 7.520 0.480 8.640 14.86 8.00 BRKS-580-5.7

The thread is a M5. This might not work as it is 3 to 5.7 mm depth.

View attachment 264081

View attachment 264080

"This might not work as it is 3 to 5.7 mm depth."

autostaretx

Erratic Member

To (mis-) quote Yoda: "Ahh... Lucky you are"I live near a United Fastener shop and they have metric bolts, too. I brought my van to them because they've helped me before and they have a super nice caliper to help me out and measure for me.

Yes, it's confusing (i recalculated the "0.9" twice).Bear with me, as I'm trying to grasp the #s here. In general, you're saying the Plusnuts are a better fit because they are far better at being forgiving for "loose fits" and do NOT require a precision hole. The M5 X 0.8 plusnut is shy by 8.0 mm by 0.53while the 10/32 is shy of the 8 mmm by 0.037. Wouldn't the 10/32 be the better fit?

"So for the closest (loose) fit, the M5 x 0.8 PlusNut comes the closest. 0.53 mm undersized instead of the 10-32 0.9 mm undersized." Is the 0.9 a typo or the 0.037 further up in your explanation. I appreciate the explanation. I'm trying to understand all the nuances of reading the chart sizes posted.

The magic number to remember is that an inch is (exactly) 25.4 mm

We can write that as 25.4 mm/inch

So: the body of the 10-32 Plus Nut is 0.272 inches, and is designed for a hole ranging from 0.273 to 0.278 inches. (shy of 8mm by 0.037 inch)

Saying that all as millimeters, 0.272 inch * 25.4 mm/inch = 6.9088 mm

The hole design is for 6.9342 to 7.0612 mm ... and 8mm is 0.9388 mm bigger than that upper "limit".

If we look at the M5 x 0.8 PlusNut, it has a body diameter of 7.48mm, for a hole size of 7.62 to 7.47 mm

7.47 mm is closer to 8mm than the 10-32's 7.06 "upper limit"

That's why i chose the M5 x 0.8 (and it keeps with your desire to be metric) ... it's a closer fit to an 8mm hole.

--dick

ECU

2006 T1n 118 Sprinter

If the dept isn't shallow enough, it wont grab the metal wall. 3mm is about 1/8", look at the thickness of your metal. The nut will squish down to the depth of it's rating. If there is too much gap, the nut spins. Spinning nuts are bad.

Different product but you can see in this picture, three depths of material it is to go through. Thick or thinner stuff.

Different product but you can see in this picture, three depths of material it is to go through. Thick or thinner stuff.

Last edited: