Midwestdrifter

Engineer In Residence

For the entertainment and education of the internets, I will be posting some details of the design and installation of the electrical system from my T1N build out  . While I have some budget constraints (cost/value is a consideration) I am attempting to do this right on the first try (I plan on having this van a long time).

. While I have some budget constraints (cost/value is a consideration) I am attempting to do this right on the first try (I plan on having this van a long time).

Anyways, I welcome comments or suggestions both on the basic design and component selection.

Pertinent Details

Primary Design Parameters

The difficulty with designing an electrical system is that most any appliances in the modern RV use electrical power in some way. For what is essentially a prototype/one off build, this presents the need for several design iterations to achieve a balance between consumption/generation and overall system size. My system is a bit unique because I wanted to avoid needing a second fuel for cooking (Yes, I know how much money I could save with a propane tank and stove).

Anyways, here is a breakdown of the major components. I have narrowed the selection to 2 configurations.

Configuration 1: Loads

Configuration 1: Power Sources and Storage

Configuration 2: Loads

Configuration 2: Power Generation and Storage

The sizing of the various components (PV panels, batteries etc) is driven by a complete energy budget. A different person using the exact same appliances may have drastically different power consumption. I have attached a PDF with the a few tables showing the load and source expectations for configuration 1. The numbers show a net solar surplus on a normal day with no alternator input.

If I get home before dark tomorrow I will take a few pictures of the solar install on the van.

. While I have some budget constraints (cost/value is a consideration) I am attempting to do this right on the first try (I plan on having this van a long time).

. While I have some budget constraints (cost/value is a consideration) I am attempting to do this right on the first try (I plan on having this van a long time).Anyways, I welcome comments or suggestions both on the basic design and component selection.

Pertinent Details

- 2004 T1N Cargo – 144in wheelbase - 6ft ceiling.

- 90AMP alternator from the factory

- No Factory Heater/Booster or AUX battery

Primary Design Parameters

- Single Fuel Only (diesel)

- Extensive Dry Camping/Boondocking (Limiting factor being fresh water)

- Cold and Warm weather Camping - No rooftop A/C (20-90F)

- No Generator (necessitates rooftop solar)

The difficulty with designing an electrical system is that most any appliances in the modern RV use electrical power in some way. For what is essentially a prototype/one off build, this presents the need for several design iterations to achieve a balance between consumption/generation and overall system size. My system is a bit unique because I wanted to avoid needing a second fuel for cooking (Yes, I know how much money I could save with a propane tank and stove).

Anyways, here is a breakdown of the major components. I have narrowed the selection to 2 configurations.

Configuration 1: Loads

- 1800W induction cooktop

- Vitrifrigo C115i – DC Fridge

- Espar Hydronic 5 heater & Isotemp 4gal Water Heater (coolant/hydronic heated)

- 20-50W Fan (used with heater core & hyrdonic for cabin heat)

- 40-80W Laptop

- 50W LCD TV/Monitor

- 20-60W LED Lighting

- MaxAir Roof Vent

- 10-25W directional Fan

Configuration 1: Power Sources and Storage

- 640W Grape Solar 160Wx4 Monocrystline Panels (already installed on van)

- 200A Bosch OEM Alternator (a bit overkill, but not much additional cost over 150A version)

- Complete PV/Inverter/Charger/Monitor system From Outback (break out the wallet, cost is $3K

)

)

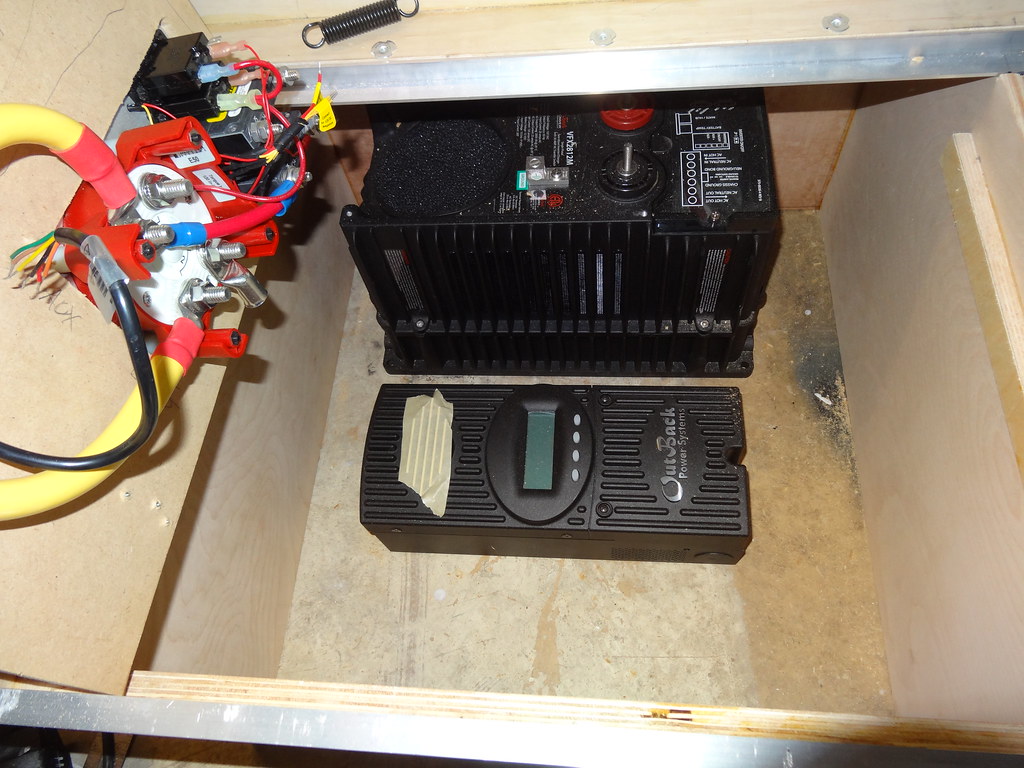

- VFX2812M Inverter Charger

- Flexmax 60 MPPT charge controller

- Mate 2 System Controller/Display

- FlexNet DC Monitor

- Hub-4 Interconnect Device

- 440-660AH Battery Bank (6xGC2 flooded or 2x8D AGM)

- 640w was the absolute maximum I could fit on my vans roof (with a roof vent). 5x160W panels would fit if the vent was not present.

- Battery bank size is based on both total AH capacity AND necessary peak output for 1800W cooktop.

Configuration 2: Loads

- (same as option 1 with a Webasto X100 Diesel cooktop replacing the Induction unit)

- Note: The X100 unit can be fitted with a blower lid for cabin heating; this may allow removal of the cabin heater core, or possibly the hydronic unit if engine heat is sufficient for water.

Configuration 2: Power Generation and Storage

- 640W Grape Solar 160Wx4 Monocrystline Panels (already installed on van)

- 200A Bosch OEM Alternator (a bit overkill, but not much additional cost over 150A version)

- MorningStar TrackStar MPPT PV controller

- Stand-alone shore power charger ~50A

- 440AH Battery Bank (4xGC2 flooded or 2x8D AGM)

- Stand-alone Battery Monitor (Xantrex or similar)

- 500-1000W Pure Sine Inverter for small electronics (most devices will natively accept DC power)

The sizing of the various components (PV panels, batteries etc) is driven by a complete energy budget. A different person using the exact same appliances may have drastically different power consumption. I have attached a PDF with the a few tables showing the load and source expectations for configuration 1. The numbers show a net solar surplus on a normal day with no alternator input.

If I get home before dark tomorrow I will take a few pictures of the solar install on the van.

Attachments

-

192.3 KB Views: 1,221

Last edited:

.

.

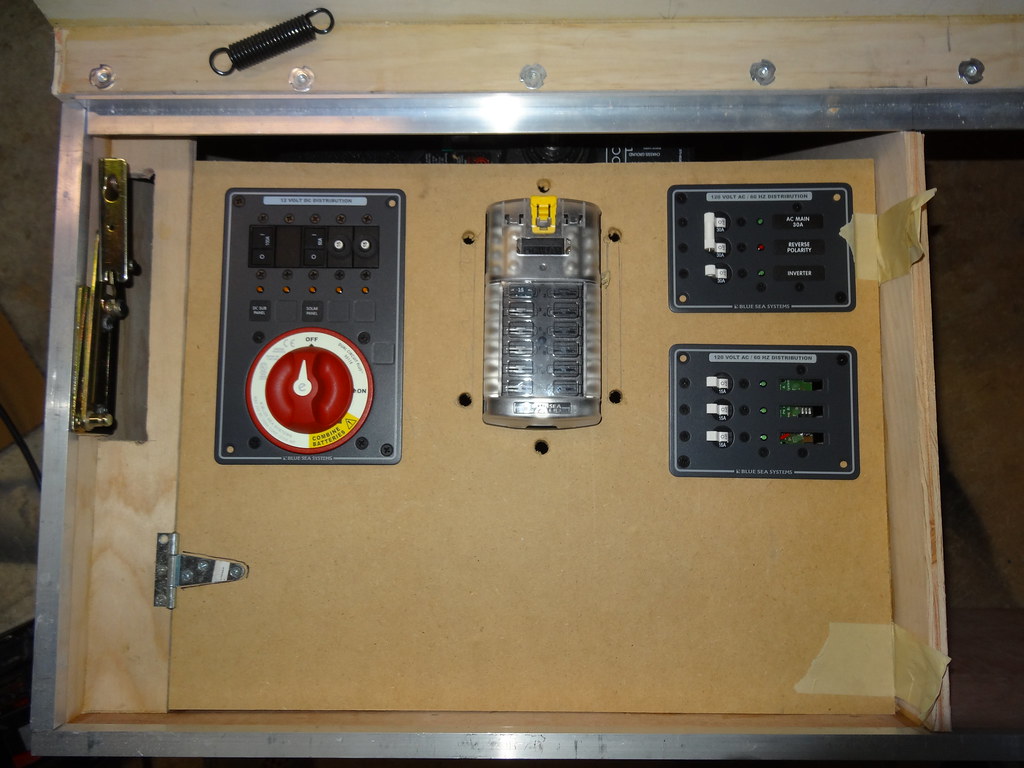

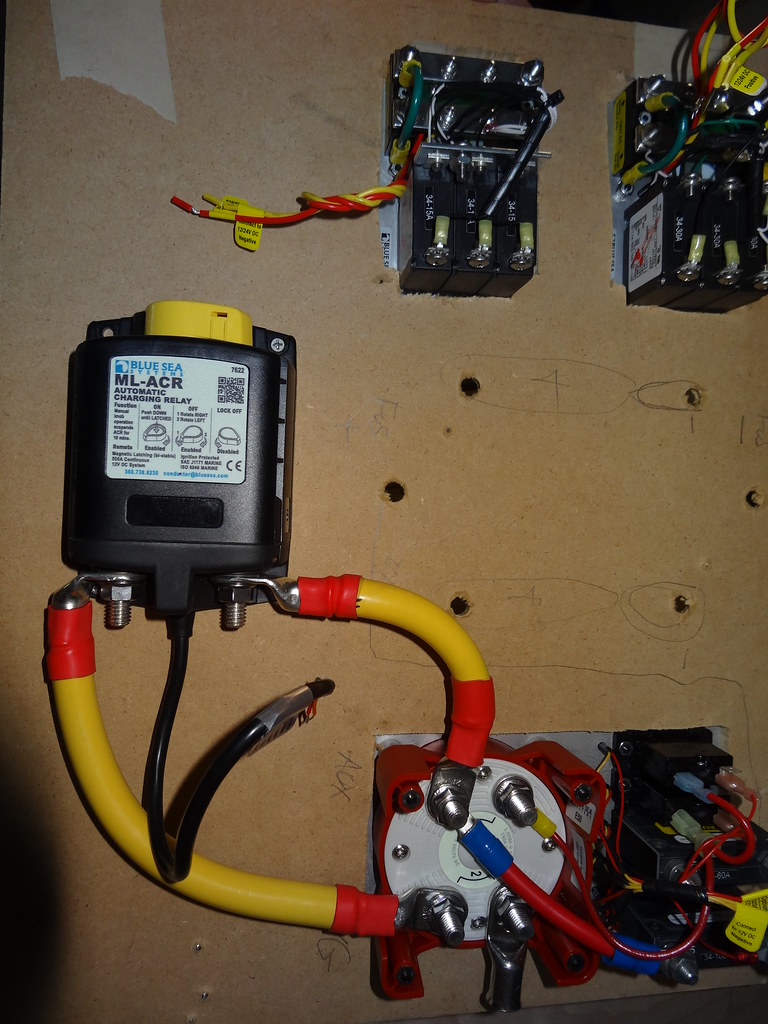

I will get this thread up to date this weekend sometime. Proper circuit protection just keeps getting more expensive... As a plus all the pretty bits and pieces look great on my coffee table.

I will get this thread up to date this weekend sometime. Proper circuit protection just keeps getting more expensive... As a plus all the pretty bits and pieces look great on my coffee table.

Such poor paint on the roof! After seeing how weak the inter-layer adhesion was, I decided to add a few #8 sheet metal screws to the mounts for peace of mind.

Such poor paint on the roof! After seeing how weak the inter-layer adhesion was, I decided to add a few #8 sheet metal screws to the mounts for peace of mind.

Since I am now looking into under chassis mounting for the batteries. I will most likely be switching to 4/0 gauge due to the longer runs needed.

Since I am now looking into under chassis mounting for the batteries. I will most likely be switching to 4/0 gauge due to the longer runs needed.