The weekend has been pretty busy and awesome. A ton of work got done and pretty happy with the progress.

The stack of parts is getting a bit large, so let's start putting some in there to get it down!

Untitled

Untitled by

Grant Wilson, on Flickr

Friday after work, decided that i was going to strip all the pieces out of the front (a pillar and b pillar trim headliner etc) so i can start running wires for the PA and speakers.

Untitled

Untitled by

Grant Wilson, on Flickr

Then I applied the sound deadening, put a ton of Thinsulate up there, and moved on to some other areas

Untitled

Untitled by

Grant Wilson, on Flickr

Untitled

Untitled by

Grant Wilson, on Flickr

Untitled

Untitled by

Grant Wilson, on Flickr

After that was finished, I went to the rear doors. Pulled the lower panels off, applied sound deadening there and thinsulate, as well as pulling the wires for the rear door speakers

Untitled

Untitled by

Grant Wilson, on Flickr

Saturday not much got done. My friend Justin came over

Untitled

Untitled by

Grant Wilson, on Flickr

Untitled

Untitled by

Grant Wilson, on Flickr

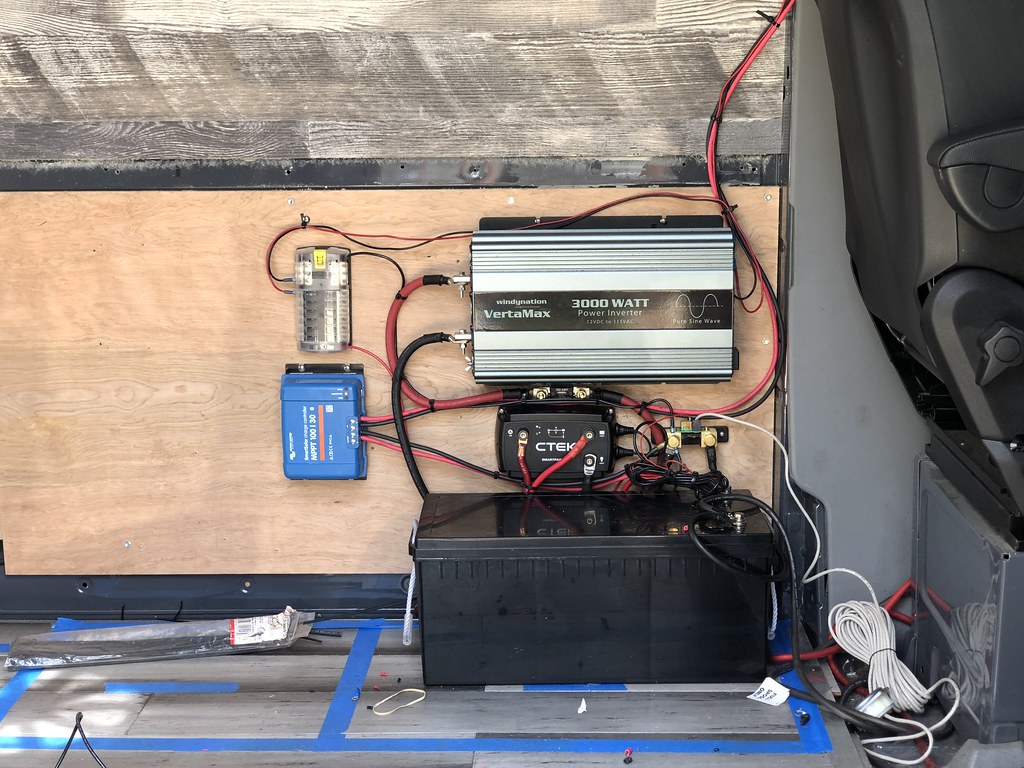

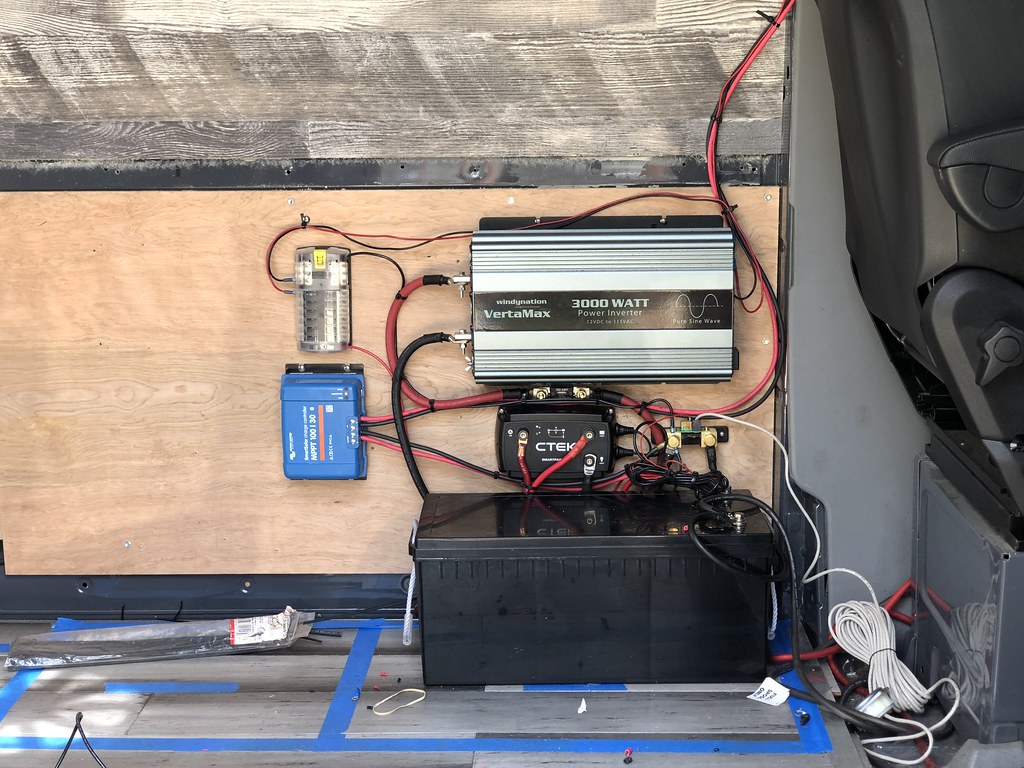

He need his electrical system installed, so i knocked it out for him in like an hour or so

Untitled

Untitled by

Grant Wilson, on Flickr

he still has to hide some cables and do some other crap, but he was headed on a trip this week and needed something functional, so i hooked it all up for him.

The one thing i did work on Saturday, was hiding the god awful wiring harness back there. I pulled the entire body harness from the headliner to the rear out of its home and removed all the clips.

Untitled

Untitled by

Grant Wilson, on Flickr

I actually pulled it all back out, and then rerouted it behind the side area as well then put it all back on sunday correctly.

Sunday was alot of wiring finishing up front and my friend Rob (the guy who bought my Subaru) helping out with sound deadening and insulation.

Untitled

Untitled by

Grant Wilson, on Flickr

I finished some wiring on the PA, mounted the siren/speaker in the front, a single row lightbar and then ran the trigger wire for the relay for the ARB compressor that I will install on Monday hopefully. The balance of the evening was spent redoing the rear harness like i mentioned above to run behind all the body panels and not to be seen again.

We got 3/4 of the sound deadning in the upper portion of hte van done. I ordered another box of sound deadedning to finish up what was needed, and am waiting on more thinsulate from Hein as well as some other parts so i can do the audio stuff. Also mounted up the rear batteries using some holddown loops and 1" webbing straps I sewed up with velcro closure stuff to keep it tied down. No batteries sliding around here!

Untitled

Untitled by

Grant Wilson, on Flickr

Untitled

Untitled by

Grant Wilson, on Flickr

Untitled

Untitled by

Grant Wilson, on Flickr

Next up is getting the flarespace flares dropped off for paint when they come in this week, Sorting a Tern Overland window, pulling the floor for insulation and running main power wire for hte Ctek Smartpass to the rear, making the rear passenger wall to mount all the electrics to, and sorting electrics out. Tons of fun!