kyrgyznomad

New member

New member here, just posted a hello in the general section and figured I'd head over here for some troubleshooting help. I've got two 2004 Jeep Grand Cherokee 2.7 CRDs in Kyrgyzstan. The motors are OM647s, so I'm hoping this is the place I can get some good info on them (I know their not Sprinters, but we can't all be perfect ). One of the Jeeps started acting up toward the end of the summer. I wasn't driving, but my client reported that it made a ticking sound at the top of a 3300 meter pass (about 11,000 feet). Since everything looked ok (temperature, oil, water, etc) we decided that he should keep going. He got about 150 km down the road when a massive amount of oil poured out of the coolant overflow. He reports that it didn't overheat, but I'm really not sure. We swapped him out for a different car and put the Jeep on a truck back to Bishkek. After trying to eliminate the normal culprit, the heat exchanger, things still weren't right so we pulled the motor. When the head came off we discovered two melted pistons. #4 is badly melted and #3 is a bit melted. Both scored the cylinder walls as well. The only known issue was that injector #2 or #3 (I can't remember) was just starting to leak a little (classic black death) and was to be fixed when he got back.

). One of the Jeeps started acting up toward the end of the summer. I wasn't driving, but my client reported that it made a ticking sound at the top of a 3300 meter pass (about 11,000 feet). Since everything looked ok (temperature, oil, water, etc) we decided that he should keep going. He got about 150 km down the road when a massive amount of oil poured out of the coolant overflow. He reports that it didn't overheat, but I'm really not sure. We swapped him out for a different car and put the Jeep on a truck back to Bishkek. After trying to eliminate the normal culprit, the heat exchanger, things still weren't right so we pulled the motor. When the head came off we discovered two melted pistons. #4 is badly melted and #3 is a bit melted. Both scored the cylinder walls as well. The only known issue was that injector #2 or #3 (I can't remember) was just starting to leak a little (classic black death) and was to be fixed when he got back.

The jeep has 129,000 km on the odometer and was running fantastic up to this point. Regular oil changes and it had a new fuel filter. There's no visible damage to the head, though we need to pressure check it. I'd like to just swap motors at this point, though I'd also like to get a better idea of what happened to prevent such expensive failures in the future.

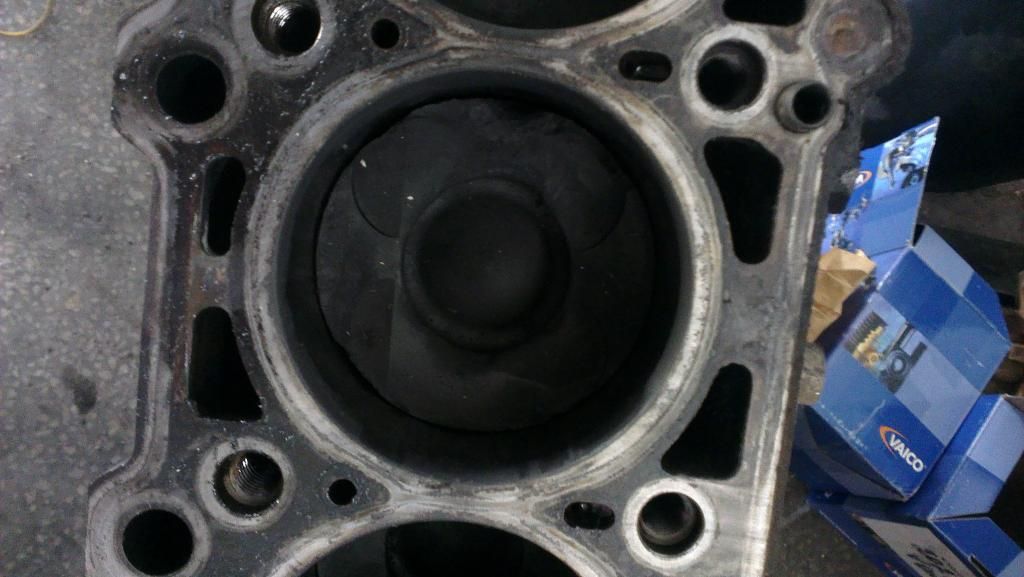

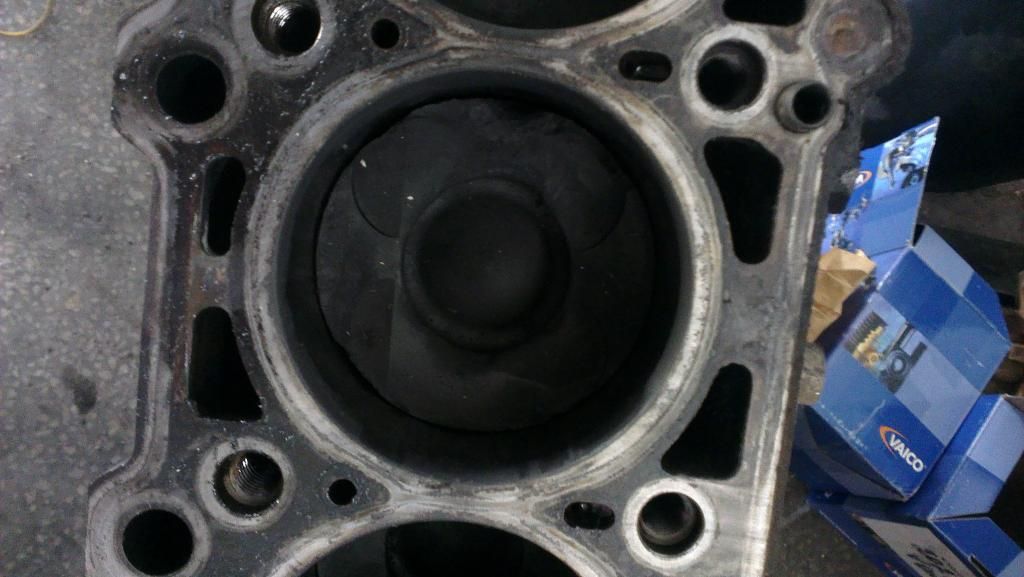

Here are a couple pics of the pistons and cylinders.

Note that not only is the outside edge toast, the inside around the "cup" is also melted and deformed.

Regarding engine swaps, can anyone comment on the compatibility of OM612 and OM647 blocks? If I can get my hands on an OM612 engine, can I just swap on my components such as injectors, computer, etc? It seems the two are really, really close.

). One of the Jeeps started acting up toward the end of the summer. I wasn't driving, but my client reported that it made a ticking sound at the top of a 3300 meter pass (about 11,000 feet). Since everything looked ok (temperature, oil, water, etc) we decided that he should keep going. He got about 150 km down the road when a massive amount of oil poured out of the coolant overflow. He reports that it didn't overheat, but I'm really not sure. We swapped him out for a different car and put the Jeep on a truck back to Bishkek. After trying to eliminate the normal culprit, the heat exchanger, things still weren't right so we pulled the motor. When the head came off we discovered two melted pistons. #4 is badly melted and #3 is a bit melted. Both scored the cylinder walls as well. The only known issue was that injector #2 or #3 (I can't remember) was just starting to leak a little (classic black death) and was to be fixed when he got back.

). One of the Jeeps started acting up toward the end of the summer. I wasn't driving, but my client reported that it made a ticking sound at the top of a 3300 meter pass (about 11,000 feet). Since everything looked ok (temperature, oil, water, etc) we decided that he should keep going. He got about 150 km down the road when a massive amount of oil poured out of the coolant overflow. He reports that it didn't overheat, but I'm really not sure. We swapped him out for a different car and put the Jeep on a truck back to Bishkek. After trying to eliminate the normal culprit, the heat exchanger, things still weren't right so we pulled the motor. When the head came off we discovered two melted pistons. #4 is badly melted and #3 is a bit melted. Both scored the cylinder walls as well. The only known issue was that injector #2 or #3 (I can't remember) was just starting to leak a little (classic black death) and was to be fixed when he got back. The jeep has 129,000 km on the odometer and was running fantastic up to this point. Regular oil changes and it had a new fuel filter. There's no visible damage to the head, though we need to pressure check it. I'd like to just swap motors at this point, though I'd also like to get a better idea of what happened to prevent such expensive failures in the future.

Here are a couple pics of the pistons and cylinders.

Note that not only is the outside edge toast, the inside around the "cup" is also melted and deformed.

Regarding engine swaps, can anyone comment on the compatibility of OM612 and OM647 blocks? If I can get my hands on an OM612 engine, can I just swap on my components such as injectors, computer, etc? It seems the two are really, really close.

).

).